A General Reference Work on

TELEPHONY, SUBSTATIONS, PARTY LINE SYSTEMS, PROTECTION, MANUAL

SWITCHBOARDS, AUTOMATIC SYSTEMS, POWER PLANTS, SPECIAL

SERVICE FEATURES, CONSTRUCTION, ENGINEERING,

OPERATION, MAINTENANCE, TELEGRAPHY, WIRELESS

TELEGRAPHY AND TELEPHONY, ETC.

Prepared by a Corps of

TELEPHONE AND TELEGRAPH EXPERTS, AND ELECTRICAL ENGINEERS OF

THE HIGHEST PROFESSIONAL STANDING

Illustrated with over Two Thousand Engravings

F O U R V O L U M E S

CHICAGO

AMERICAN SCHOOL OF CORRESPONDENCE

1919

COPYRIGHT, 1911, 1912,

BY

AMERICAN SCHOOL OF CORRESPONDENCE

COPYRIGHT, 1911, 1912

BY

AMERICAN TECHNICAL SOCIETY

Entered at Stationers' Hall, London

All Rights Reserved

![]() The present day development of the "talking wire" has

annihilated both time and space, and has enabled men

thousands of miles apart to get into almost instant

communication. The user of the telephone and the telegraph

forgets the tremendousness of the feat in the simplicity of its

accomplishment; but the man who has made the feat possible

knows that its very simplicity is due to the complexity of the

principles and appliances involved; and he realizes his need of

a practical, working understanding of each principle and its

application. The Cyclopedia of Telephony and Telegraphy presents

a comprehensive and authoritative treatment of the whole

art of the electrical transmission of intelligence.

The present day development of the "talking wire" has

annihilated both time and space, and has enabled men

thousands of miles apart to get into almost instant

communication. The user of the telephone and the telegraph

forgets the tremendousness of the feat in the simplicity of its

accomplishment; but the man who has made the feat possible

knows that its very simplicity is due to the complexity of the

principles and appliances involved; and he realizes his need of

a practical, working understanding of each principle and its

application. The Cyclopedia of Telephony and Telegraphy presents

a comprehensive and authoritative treatment of the whole

art of the electrical transmission of intelligence.

![]() The communication engineer—if so he may be called—requires

a knowledge both of the mechanism of his instruments and of

the vagaries of the current that makes them talk. He requires as

well a knowledge of plants and buildings, of office equipment,

of poles and wires and conduits, of office system and time-saving

methods, for the transmission of intelligence is a business as

well as an art. And to each of these subjects, and to all others

pertinent, the Cyclopedia gives proper space and treatment.

The communication engineer—if so he may be called—requires

a knowledge both of the mechanism of his instruments and of

the vagaries of the current that makes them talk. He requires as

well a knowledge of plants and buildings, of office equipment,

of poles and wires and conduits, of office system and time-saving

methods, for the transmission of intelligence is a business as

well as an art. And to each of these subjects, and to all others

pertinent, the Cyclopedia gives proper space and treatment.

![]() The sections on Telephony cover the installation, maintenance,

and operation of all standard types of telephone systems;

they present without prejudice the respective merits of manual

and automatic exchanges; and they give special attention to

the prevention and handling of operating "troubles." The

sections on Telegraphy cover both commercial service and train

dispatching. Practical methods of wireless communication—both

by telephone and by telegraph—are thoroughly treated.

The sections on Telephony cover the installation, maintenance,

and operation of all standard types of telephone systems;

they present without prejudice the respective merits of manual

and automatic exchanges; and they give special attention to

the prevention and handling of operating "troubles." The

sections on Telegraphy cover both commercial service and train

dispatching. Practical methods of wireless communication—both

by telephone and by telegraph—are thoroughly treated.

![]() The drawings, diagrams, and photographs incorporated into

the Cyclopedia have been prepared especially for this work;

and their instructive value is as great as that of the text itself.

They have been used to illustrate and illuminate the text, and

not as a medium around which to build the text. Both drawings

and diagrams have been simplified so far as is compatible

with their correctness, with the result that they tell their own

story and always in the same language.

The drawings, diagrams, and photographs incorporated into

the Cyclopedia have been prepared especially for this work;

and their instructive value is as great as that of the text itself.

They have been used to illustrate and illuminate the text, and

not as a medium around which to build the text. Both drawings

and diagrams have been simplified so far as is compatible

with their correctness, with the result that they tell their own

story and always in the same language.

![]() The Cyclopedia is a compilation of many of the most valuable

Instruction Papers of the American School of Correspondence,

and the method adopted in its preparation is that which this

School has developed and employed so successfully for many

years. This method is not an experiment, but has stood the

severest of all tests—that of practical use—which has demonstrated

it to be the best yet devised for the education of the

busy, practical man.

The Cyclopedia is a compilation of many of the most valuable

Instruction Papers of the American School of Correspondence,

and the method adopted in its preparation is that which this

School has developed and employed so successfully for many

years. This method is not an experiment, but has stood the

severest of all tests—that of practical use—which has demonstrated

it to be the best yet devised for the education of the

busy, practical man.

![]() In conclusion, grateful acknowledgment is due to the staff

of authors and collaborators, without whose hearty co-operation

this work would have been impossible.

In conclusion, grateful acknowledgment is due to the staff

of authors and collaborators, without whose hearty co-operation

this work would have been impossible.

Manual Switchboards By K. B. Miller and S. G. McMeen[A] Page[B] 11

CHAPTER XXII—Common-Battery Switchboards—Line Signals—Cord Circuit—Lamps—Mechanical Signals—Relays—Jacks—Switchboard Assembly

CHAPTER XXIII—Transfer Switchboard—Transfer Lines—Handling Transfers

CHAPTER XXIV—Multiple Switchboard—Busy Test—Influence of Traffic

CHAPTER XXV—Magneto-Multiple Switchboard—Multiple Boards: Series, Branch-Terminal, Modern Magneto, Common-Battery

CHAPTER XXVI—Western Electric No. 1 Relay Board—Western Electric No. 10 Board—Types of Multiple Boards—Apparatus

CHAPTER XXVII—Trunking—Western Electric and Kellogg Trunk Circuits

Automatic Systems By K. B. Miller and S. G. McMeen Page 135

CHAPTER XXVIII—Automatic vs. Manual—Operation

CHAPTER XXIX—Selecting Switch—Line Switch—Trunking Systems—Two- and Three-Wire Systems—Subscriber's Station Apparatus—First and Second Selector Operation—Connector—Release after Conversation—Multi-Office System—Automatic Sub-Offices—Rotary Connector—Party Lines—Two-Wire Automatic System

CHAPTER XXX—Lorimer System—Central-Office Apparatus—Operation

CHAPTER XXXI—Automanual System—Operation—Subscriber's Apparatus—Operator's Equipment—Switching Equipment—Distribution of Calls—Connection—Speed

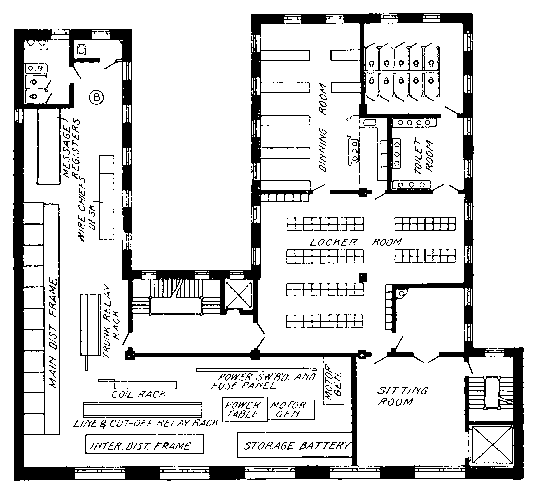

Power Plants and Buildings By K. B. Miller and S. G. McMeen Page 227

CHAPTER XXXII—Currents Employed—Types—Operator's Transmitter Supply—Ringing-Current Supply—Auxiliary Signaling Current—Primary Sources—Duplicate Apparatus—Storage Batteries—Power Switchboards—Circuits

CHAPTER XXXIII—Central-Office Building—Arrangement of Apparatus—Manual Offices—Automatic Offices

Special Service Features By K. B. Miller and S. G. McMeen Page 271

CHAPTER XXXIV—Private-Branch Exchanges—Switchboards—Supervision—With Automatic Offices—Battery Supply—Ringing Current

CHAPTER XXXV—Inter-Communicating Systems—Magneto System—Common-Battery Systems—Types

CHAPTER XXXVI—Long-Distance Switching—Operator's Orders—Trunking—Way Stations

CHAPTER XXXVII—Traffic

CHAPTER XXXVIII—Measured Service—Charging—Rates—Toll Service—Local Service

Telegraph and Railway Work By K. B. Miller and S. G. McMeen Page 321

CHAPTER XXXIX—Phantom, Simplex, and Composite Circuits—Ringing—Railway Composite

CHAPTER XL—Telephone Train Dispatching—Railroad Conditions—Transmitting Orders—Apparatus—Telephone Equipment—Types of Circuits—Test Boards—Blocking Sets—Dispatching on Electric Railways

Review Questions Page 359

Index Page 373

[A] For professional standing of authors, see list of Authors and Collaborators at front of volume.

[B] For page numbers, see foot of pages.

GROSSE POINT EXCHANGE RACK

Detroit Home Telephone Company, Detroit, Mich.

The Dean Electric Co.

LINE SIDE OF LARGE MAIN DISTRIBUTING FRAME

PORTION OF TERMINAL ROOM OF LARGE COMMON-BATTERY OFFICE

Prospect Office, New York Telephone Co.

CABLE TURNING SECTIONS, BETWEEN A AND B BOARDS

Cortlandt Office, New York Telephone Co.

CABLE RUN FROM INTERMEDIATE FRAME TO MULTIPLE

Cortlandt Office, New York Telephone Co.

WESTERN ELECTRIC COMPANY TYPICAL CHARGING OUTFIT AT DAWSON, GEORGIA

DEAN HARMONIC CONVERTER

Dry Cell Type for Magneto Exchange.

The Dean Electric Co.

POWER SWITCHBOARD FOR MEDIUM-SIZED OFFICE

Mercury Arc Rectifier Panel and Transformer at Right.

GAS ENGINE AND POWER BOARD

Citizens' Telephone Co., Racine, Wis.

The Dean Electric Co.

POWER MACHINERY

Citizens' Telephone Company, Racine, Wis.

The Dean Electric Co.

POWER APPARATUS FOR COMMON-BATTERY MANUAL OFFICE OF MEDIUM SIZE

THE POWER AND WIRE CHIEF'S ROOM OF THE EXCHANGE AT WEBB CITY, MISSOURI

RINGING AND CHARGING MACHINES AND POWER BOARD

Plaza Office, New York Telephone Co.

POWER PLANT FOR AUTOMATIC SWITCHBOARD EQUIPMENT

Bay Cities Home Telephone Company, Berkeley, Cal.

WESTERN ELECTRIC COMPANY BATTERY ROOM AT MONMOUTH, ILLINOIS

WESTERN ELECTRIC MOTOR-GENERATOR CHARGING SET

WESTERN ELECTRIC RINGING MACHINE

FRONT OF LONG-DISTANCE POWER BOARD

U.S. Telephone Company, Cleveland, Ohio.

The Dean Electric Co.

Advantages of Common-Battery Operation. The advantages of the common-battery system of operation, alluded to in Chapter XIII, may be briefly summarized here. The main gain in the common-battery system of supply is the simplification of the subscribers' instruments, doing away with the local batteries and the magneto generators, and the concentration of all these many sources of current into one single source at the central office. A considerable saving is thus effected from the standpoint of maintenance, since the simpler common-battery instrument is not so likely to get out of order and, therefore, does not have to be visited so often for repairs, and the absence of local batteries, of course, makes the renewal of the battery parts by members of the maintenance department, unnecessary. Another decided advantage in the common-battery system is the fact that the centralized battery stands ready always to send current over the line when the subscriber completes the circuit of the line at his station by removing his receiver from its hook. The common-battery system, therefore, lends itself naturally to the purposes of automatic signaling, since it is only necessary to place at the central office a device in the circuit of each line that will be responsive to the current which flows from the central battery when the subscriber removes his receiver from its hook. It is thus that the subscriber is enabled automatically to signal the central office when he desires a connection; and as will be shown, it is by the same sort of means, associated with the cord circuits used in connecting his line with some other line, that the operator is automatically notified when a disconnection is desired, the cessation of current through the subscriber's line when he hangs up his receiver being made to actuate certain responsive devices which are associated with the cord at that time connected with his line, and which convey the proper disconnect signal to the operator.

Concentration of sources of energy into a single large unit, the simplification of the subscriber's station equipment, and the ready adaptability to automatic signaling from the subscriber to the central office are, therefore, the reasons for the existence of the common-battery system.

Common Battery vs. Magneto. It must not be supposed, however, that the common-battery system always has advantages over the magneto system, and that it is superior to the magneto or local-battery system for all purposes. It is the outward attractiveness of the common-battery system and the arguments in its favor, so readily made by over-zealous salesmen, that has led, in many cases, to the adoption of this system when the magneto system would better have served the purpose of utility and economy.

To say the least, the telephone transmission to be had from common-battery systems is no better than that to be had from local-battery systems, and as a rule, assuming equality in other respects, it is not as good. It is perhaps true, however, that under average conditions common-battery transmission is somewhat better, because whereas the local batteries at the subscribers' stations in the local-battery system are not likely to be in uniformly first-class condition, the battery in a common-battery system will be kept up to its full voltage except under the grossest neglect.

The places in which the magneto, or local-battery, system is to be preferred to the common-battery system, in the opinion of the writers, are to be found in the small rural communities where the lines have a rather great average length; where a good many subscribers are likely to be found on some of the lines; where the sources of electrical power available for charging storage batteries are likely either not to exist, or to be of a very uncertain nature; and where it is not commercially feasible to employ a high-grade class of attendants, or, in fact, any attendant at all other than the operator at the central office.

In large or medium-sized exchanges it is always possible to procure suitable current for charging the storage batteries required in common-battery systems, and it is frequently economical, on account of the considerable quantity of energy that is thus used, to establish a generating plant in connection with the central office for developing the necessary electrical energy. In very small rural [Page 13]places there are frequently no available sources of electrical energy, and the expense of establishing a power plant for the purpose cannot be justified. But even if there is an electric light or railway system in the small town, so that the problem of available current supply does not exist, the establishment of a common-battery system with its storage battery and the necessary charging machinery requires the daily attendance at the central office of some one to watch and care for this battery, and this, on account of the small gross revenue that may be derived from a small telephone system, often involves a serious financial burden.

There is no royal road to a proper decision in the matter, and no sharp line of demarcation may be drawn between the places where common-battery systems are superior to magneto and vice versā. It may be said, however, that in the building of all new telephone plants having over about 500 local subscribers, the common-battery system is undoubtedly superior to the magneto. If the plant is an old one, however, and is to be re-equipped, the continuance of magneto apparatus might be justified for considerably larger exchanges than those having 500 subscribers.

Telephone operating companies who have changed over the equipment of old plants from magneto to common battery have sometimes been led into rather serious difficulty, owing to the fact that their lines, while serving tolerably well for magneto work, were found inadequate to meet the more exacting demands of common-battery work. Again in an old plant the change from magneto to common-battery equipment involves not only the change of switchboards, but also the change of subscribers' instruments that are otherwise good, and this consideration alone often, in our opinion, justifies the replacing of an old magneto board with a new magneto board, even if the exchange is of such size as to demand a small multiple board.

Where the plant to be established is of such size as to leave doubt as to whether a magneto or a common-battery switchboard should be employed, the questions of availability of the proper kind of power for charging the batteries, the proper kind of help for maintaining the batteries and the more elaborate central-office equipment, the demands and previous education of the public to be served, all are factors which must be considered in reaching the decision.

It is not proper to say that anything like all exchanges having fewer than 500 local lines, should be equipped with magneto service. Where all the lines are short, where suitable power is available, and where a good grade of attendants is available—as, for instance, in the case of private telephone exchanges that serve some business establishment or other institution located in one building or a group of buildings—the common-battery system is to be recommended and is largely used, even though it may have but a dozen or so subscribers' lines. It is for such uses, and for use in those regular public-service exchange systems where the conditions are such as to warrant the common-battery system, and yet where the number of lines and the traffic are small enough to be handled by such a small group of operators that any one of them may reach over the entire face of the board, that the simple non-multiple common-battery system finds its proper field of usefulness.

Line Signals. The principles and means by which the subscriber is enabled to call the central-office operator in a common-battery system have been referred to briefly in Chapter III. We will review these at this point and also consider briefly the way in which the line signals are associated with the connective devices in the subscribers' lines.

Direct-Line Lamp. The simplest possible way is to put the line signal directly in the circuit of the line in series with the central-office battery, and so to arrange the jack of the corresponding line that the circuit through the line signal will be open when the operator inserts a plug into that jack. This arrangement is shown in Fig. 307 where the subscriber's station at the left is indicated in the simplest of its forms. It is well to repeat here that in all common-battery manual systems, the subscriber's station equipment, regardless of the arrangement or type of its talking and signaling apparatus, must have these features: First, that the line shall be normally open to direct currents at the subscriber's station; second, that the line shall be closed to direct currents when the subscriber removes his receiver from its hook in making or in answering a call; third, that the line normally, although open to direct currents, shall afford a proper path for alternating or varying currents through the signal receiving device at the sub-station. The subscriber's station arrangement shown in Fig. 307, and those immediately following, [Page 15]is the simplest arrangement that possesses these three necessary features for common-battery service.

Considering the arrangement at the central office, Fig. 307, the two limbs of the line are permanently connected to the tip and sleeve contacts of the jack. These two main contacts of the jack normally engage two anvils so connected that the tip of the jack is ordinarily connected through its anvil to ground, while the sleeve of the jack is normally connected through its anvil to a circuit leading through the line signal—in this case a lamp—and the common battery, and thence to ground. The operation is obvious. Normally no current may flow from the common battery through the signal because the line is open at the subscriber's station. The removal of the subscriber's receiver from its hook closes the circuit of the line and allows the current to flow through the lamp, causing it to glow. When the operator inserts the plug into the jack, in response to the call, the circuit through the lamp is cut off at the jack and the lamp goes out.

This arrangement, termed the direct-line lamp arrangement, is largely used in small common-battery telephone systems where the lines are very short, such as those found in factories or other places where the confines of the exchange are those of a building or a group of neighboring buildings. Many of the so-called private-branch exchanges, which will be considered more in detail in a later chapter, employ this direct-line lamp arrangement.

Direct-Line Lamp with Ballast. Obviously, however, this direct-line lamp arrangement is not a good one where the lines vary widely in length and resistance. An incandescent lamp, as is well known, must not be subjected to too great a variation in current. If [Page 16]the current that is just right in amount to bring it to its intended degree of illumination is increased by a comparatively small amount, the life of the lamp will be greatly shortened, and too great an increase will result in the lamp's burning out immediately. On the other hand, a current that is too small will not result in the proper illumination of the lamp, and a current of one-half the proper normal value will just suffice to bring the lamp to a dull red glow. With lines that are not approximately uniform in length and resistance the shorter lines would afford too great a flow of current to the lamps and the longer lines too little, and there is always the danger present, unless means are taken to prevent it, that if a line becomes short-circuited or grounded near the central office, the lamp will be subjected to practically the full battery potential and, therefore, to such a current as will burn it out. One of the very ingenious and, we believe, promising methods that has been proposed to overcome this difficulty is that of the iron-wire ballast, alluded to in Chapter III. This, it will be remembered, consists of an iron-wire resistance enclosed in a vacuum chamber and so proportioned with respect to the flow of current that it will be subjected to a considerable heating effect by the amount of current that is proper to illuminate the lamp. As has already been pointed out, carbon has a negative temperature coefficient, that is, its resistance decreases when heated. Iron, on the other hand, has a positive temperature coefficient, its resistance increasing when heated. When such an iron-wire ballast is put in series with the incandescent lamp forming the line signal, as shown in Fig. 308, it is seen that the resistance of the carbon in the lamp filament and of the iron in the ballast will act in opposite ways when the current increases or decreases. An increase of current will tend to heat up the iron wire of the ballast and, therefore, increase its resistance, [Page 17]and the ballast is so proportioned that it will hold the current that may flow through the lamp within the proper maximum and minimum limits, regardless of the resistance of the line in which the lamp is used. This arrangement has not gone into wide use up to the present time.

Line Lamp with Relay. By far the most common method of associating the line lamp with the line is to employ a relay, of which the actuating coil is in the line circuit, this relay serving to control a local circuit containing the battery and the lamp. This arrangement and the way in which these parts are associated with the jack are clearly indicated in Fig. 309. Here the relay may receive any amount of current, from the smallest which will cause it to pull up its armature, to the largest which will not injure its winding by overheat. Relays may be made which will attract their armatures at a certain minimum current and which will not burn out when energized by currents about ten times as large, and it is thus seen that a very large range of current through the relay winding is permissible, and that, therefore, a very great latitude as to line resistance is secured. On the other hand, it is obvious that the lamp circuit, being entirely local, is of uniform resistance, the lamp always being subjected, in the arrangement shown, to practically the full battery potential, the lamp being selected to operate on that potential.

Pilot Signals. In the circuits of Figs. 307, 308, and 309, but a single line and its associated apparatus is shown, and it may not be altogether clear to the uninitiated how it is that the battery shown in those figures may serve, without interference of any function, a larger number of lines than one. It is to be remembered that this battery [Page 18]is the one which serves not only to operate the line signals, but also to supply talking current to the subscribers and to supply current for the operation of the cord-circuit signals after the cord circuits are connected with the lines.

In Fig. 310 this matter is made clear with respect to the association of this common battery with the lines for operating the line signals, and also another important feature of common-battery work is brought out, viz, the pilot lamp and its association with a group of line lamps. Three subscribers' lines only are shown, but this serves clearly to illustrate the association of any larger number of lines with the common battery. Ignoring at first the pilot relay and the pilot lamp, it will be seen that each of the tip-spring anvils of the jacks is connected to a common wire 1 which is grounded. Each of the sleeve-contact anvils is connected through the coil of the line relay to another common wire 2, which connects with the live side of the common battery. Obviously, therefore, this arrangement corresponds with that of Fig. 309, since the battery may furnish current to energize any one of the line relays upon the closure of the circuit of the corresponding line. Each of the relay armatures in Fig. 310 is connected to ground.

Here we wish to bring out an important thing about telephone circuit diagrams which is sometimes confusing to the beginner, but which really, when understood, tends to prevent confusion. The showing of a separate ground for each of the line-relay armatures does not mean that literally each one of these armatures is connected by a separate wire to earth, and it is to be understood that the three separate grounds shown in connection with these relay armatures is meant to indicate just such a set of affairs as is shown in connection with the tip-spring anvils of the jacks, all of which are connected to a common wire which, in turn, is grounded. Obviously, the result is the same, but in the case of this particular diagram it is seen that a great deal of crossing of lines is prevented by showing a separate ground at each one of the relay armatures. The same practice is followed in connection with the common battery. Sometimes it is very inconvenient in a complicated diagram to run all of the wires that are supposed to connect with one terminal of the battery across the diagram to represent this connection. It is permissible, therefore, and in fact desirable, that separate battery symbols be shown [Page 19]wherever by so doing the diagram will be simplified, the understanding being, in the absence of other information or of other indications, that the same battery is referred to, just as the same ground is referred to in connection with the relay armatures in the figure under discussion.

Each line lamp in Fig. 310 is shown connected on one hand to its corresponding line relay contact and on the other hand to a common wire which leads through the winding of the pilot relay to the live side of the battery. It is obvious here that whenever any one of the line relays attracts its armature the local circuit containing the corresponding lamp and the common battery will be closed and the lamp illuminated.

Whenever any line relay operates, the current, which is supplied to its lamp, must come through the pilot-relay winding, and if a number of line relays are energized, then the current flow of the corresponding lamps must flow through this relay winding. Therefore, this relay winding must be of low resistance, so that the drop through its winding may not be sufficient to interfere with the proper burning of the lamps, even though a large number of lamps be fed simultaneously through it. The pilot relay must be so sensitive that the current, even through one lamp, will cause it to attract its armature. When it does attract its armature it causes illumination of the pilot lamp in the same way that the line relays cause the illumination of the line lamps.

The pilot lamp, which is commonly associated with a group of line lamps that are placed on any one operator's position of the switchboard, is located in a conspicuous place in the switchboard cabinet and is [Page 20]provided with a larger lens so as to make a more striking signal. As a result, whenever any line lamp on a given position lights, the pilot lamp does also and serves to attract the attention, even of those located in distant portions of the room, to the fact that a call exists on that position of the board, the line lamp itself, which is simultaneously lighted, pointing out the particular line on which the call exists.

Pilot lamps, in effect, perform similar service to the night alarm in magneto boards, but, of course, they are silent and do not attract attention unless within the range of vision of the operator. They are used not only in connection with line lamps, but also in connection with the cord-circuit lamps or signals, as will be pointed out.

Cord Circuit. Battery Supply. Were it not for the necessity of providing for cord-circuit signals in common-battery switchboards, the common-battery cord circuit would be scarcely more complex than that for magneto working. Stripped of all details, such as signals, ringing and listening keys, and operator's equipment, cord circuits of three different types are shown in Figs. 311, 312, and 313. These merely illustrate the way in which the battery is associated with the cord circuits and through them with the line circuits for supplying current for talking purposes to the subscribers. It is thought that this matter will be clear in view of the discussion of the methods by which current is supplied to the subscribers' transmitters in common-battery systems as discussed in Chapter XIII. While the arrangements in this respect of Figs. 311, 312, and 313 illustrate [Page 21]only three of the methods, these three are the ones that have been most widely and successfully used.

Supervisory Signals. The signals that are associated with the cord circuits are termed supervisory signals because of the fact that by their means the operator is enabled to supervise the condition of the lines during times when they are connected for conversation. The operation of these supervisory signals may be best understood by considering the complete circuits of a simple switchboard and must be studied in conjunction with the circuits of the lines as well as those of the cords.

Complete Circuit. Such complete circuits are shown in Fig. 314. The particular arrangement indicated is that employed by the Kellogg Company, and except for minor details may be considered as typical of other makes also. Two subscribers' lines are shown extending from Station A and Station B, respectively, to the central office. The line wires are shown terminating in jacks in the same manner as indicated in Figs. 307, 308, and 309, and their circuits are normally continued from these jacks to the ground on one side and to the line relay and battery on the other. The jack in this case has three contacts adapted to register with three corresponding [Page 22]contacts in each of the plugs. The thimble of the jack in this case forms no part of the talking circuit and is distinct from the two jack springs which form the line terminals. It and the auxiliary contact 1 in each of the plugs with which it registers, are solely for the purpose of co-operating in the control of the supervisory signals.

The tip and sleeve strands of the cord are continuous from one plug to the other except for the condensers. The two batteries indicated in connection with the cord circuit are separate batteries, a characteristic of the Kellogg system. One of these batteries serves to supply current to the tip and sleeve strand of the cord circuit through the two windings 3 and 4, respectively, of the supervisory relay connected with the answering side of the cord circuit, while the other battery similarly supplies current through the windings 5 and 6 of the supervisory relay associated with the calling side of the cord circuit. The windings of these relays, therefore, act as impedance coils and the arrangement by which battery current is supplied to the cord circuits and, therefore, to the lines of the connected subscribers, is seen to be the combined impedance coil and condenser arrangement discussed in Chapter XIII.

As soon as a plug is inserted into the jack of a line, the line relay will be removed from the control of the line, and since the two strands of the cord circuit now form continuations of the two line conductors, the supervisory relay will be substituted for the line relay and will be under control of the line. Since all of the current which passes to the line after a plug is inserted must pass through the cord-circuit connection and through the relay windings, and since current can only flow through the line when the subscriber's receiver is off its hook, it follows that the supervisory relays will only be energized after the corresponding plug has been inserted into a jack of the line and after the subscriber has removed his receiver. Unlike the line relays, the supervisory relays open their contacts to break the local circuits of the supervisory lamps 7 and 8 when the relay coils are energized, and to close them when de-energized; but the armatures of the supervisory relays do alone control the circuits of the supervisory lamps. These circuits are normally held open in another place, that is, between the plug contacts 1 and the jack thimbles. It is only, therefore, when a plug is inserted into a jack and when the supervisory relay is de-energized, that the supervisory [Page 23]lamp may be lighted. When a plug is inserted into a jack and when the corresponding supervisory relay is de-energized, the circuit may be traced from ground at the cord-circuit batteries through the left-hand battery, for instance, through lamp 7, thence through the contacts of the supervisory relay to the contact 1 of the plug, thence through the thimble of the jack to ground. When a plug is inserted into the jack, therefore, the necessary arrangements are completed for the supervisory lamp to be under the control of the subscriber. Under this condition, whenever the subscriber's receiver is on its hook, the circuit of the line will be broken, the supervisory relay will be de-energized, and the supervisory lamp will be lighted. When, on the other hand, the subscriber's receiver is off its hook, the circuit of the line will be complete, the supervisory relay will be energized, and the supervisory lamp will be extinguished.

Salient Features of Supervisory Operation. It will facilitate the student's understanding of the requirements and mode of operation of common-battery supervisory signals in manual systems, whether simple or multiple, if he will firmly fix the following facts in his mind. In order that the supervisory signal may become operative at all, some act must be performed by the operator—this being usually the act of plugging into a jack—and then, until the connection is taken down, the supervisory signal is under the control of the subscriber, and it is displayed only when the subscriber's receiver is placed on its hook.

Cycle of Operations. We may now trace through the complete cycle of operations of the simple common-battery switchboard, the circuits of which are shown in Fig. 314. Assume all apparatus in its normal condition, and then assume that the subscriber at Station A removes his receiver from its hook. This pulls up the line relay and lights the line lamp, the pilot relay also pulling up and lighting the common pilot lamp which is not shown. In response to this call, the operator inserts the answering plug and throws her listening key L.K. The operator's talking set is thus bridged across the cord circuit and she is enabled to converse with the calling subscriber. The answering supervisory lamp 7 did not light when the operator inserted the answering plug into the jack, because, although the contacts in the lamp circuit were closed by the plug contact 1 engaging the thimble of the jack, the lamp circuit was held open by the [Page 24]attraction of the supervisory relay armature, the subscriber's receiver being off its hook. Learning that the called-for subscriber is the one at Station B, the operator inserts the calling plug into the jack at that station and presses the ringing key R.K., in order to ring the bell. The act of plugging in, it will be remembered, cuts off the line-signaling apparatus from connection with that line. As the subscriber at Station B was not at his telephone when called and his receiver was, therefore, on its hook, the insertion of the calling plug did not energize the supervisory relay coils 5 and 6, and, therefore, that relay did not attract its armature. The supervisory lamp 8 was thus lighted, the circuit being from ground through the right-hand cord-circuit battery, lamp 8, back contacts of the supervisory relay, third strand of the cord to contact 1 of the calling plug, and thence to ground through the thimble of the jack. The lighting of this lamp is continued until the party at Station B responds by removing his receiver from its hook, which completes the line circuit, energizes relay windings 5 and 6, causes that relay to attract its armature, and thus break the circuit of the lamp 8. Both supervisory lamps remain out as long as the two subscribers are conversing, but when either one of them hangs up his receiver the corresponding supervisory relay becomes de-energized and the corresponding lamp lights. When both of the lamps become illuminated, the operator knows that both subscribers are through talking and she takes down the connection.

Countless variations have been worked in the arrangement of the line and cord circuits, but the general mode of operation of this particular circuit chosen for illustration is standard and should be thoroughly mastered. The operation of other arrangements will be readily understood from an inspection of the circuits, once the fundamental mode of operation that is common to all of them is well in mind.

Lamps. The incandescent lamps used in connection with line and supervisory signals are specially manufactured, but differ in no sense from the larger lamps employed for general lighting purposes, save in the details of size, form, and method of mounting. Usually these lamps are rated at about one-third candle-power, although they have a somewhat larger candle-power as a rule. They are manufactured to operate on various voltages, the most usual operating [Page 25]pressures being 12, 24, and 48 volts. The 24-volt lamp consumes about one-tenth of an ampere when fully illuminated, the lamp thus consuming about 2.4 watts. The 12- and 48-volt lamps consume about the same amount of energy and corresponding amounts of current.

Lamp Mounting. The usual form of screw-threaded mounting employed in lamps for commercial lighting was at first applied to the miniature lamps used for switchboard work, but this was found unsatisfactory and these lamps are now practically always provided with two contact strips, one on each side of the glass bulb, these strips forming respectively the terminals for the two ends of the filament within. Such a construction of a common form of lamp is shown in Fig. 315, where these terminals are indicated by the numerals 1 and 2, 3 being a dry wooden block arranged between the terminals at one end for securing greater rigidity between them.

The method of mounting these lamps is subject to a good deal of variation in detail, but the arrangement is always such that the lamp is slid in between two metallic contacts forming terminals of the circuit in which the lamp is to operate. Such an arrangement of springs and the co-operating mounting forming a sort of socket for the reception of switchboard lamps is referred to as a lamp jack. These are sometimes individually mounted and sometimes mounted in strips in much the same way that jacks are mounted in strips. A strip of lamp jacks as manufactured by the Kellogg Company is [Page 26]shown in Fig. 316. The opalescent lens is adapted to be fitted in front of the lamp after it has been inserted into the jack. Fig. 317 gives an excellent view of an individually-mounted lamp jack with its lamp and lens, this also being of Kellogg manufacture. This figure shows a section of the plug shelf which is bored to receive a lamp. In order to protect the lamps and lenses from breakage, due to the striking of the plugs against them, a metal shield is placed over the lens, as shown in this figure, this being so cut away as to allow sufficient openings for the light to shine through. Sometimes instead of employing lenses in front of the lamps, a flat piece of translucent material is used to cover the openings of the lamp, this being protected by suitable perforated strips of metal. A strip of lamp jacks employing this feature is shown in Fig. 318, this being of Dean manufacture. An advantage of this for certain types of work is that the flat translucent plate in front of the lamp may readily carry designating marks, such as the number of the line or something to indicate the character of the line, which marks may be readily changed as required.

In the types made by some manufacturers the only difference between the pilot lamp and the line lamp is in the size of the lens in front of it, the jack and the lamp itself being the same for each, while others use a larger lamp for the pilot. In Fig. 319 are shown two individual lamp jacks, the one at the top being for supervisory lamps and the one at the bottom being provided with a large lens for serving as a pilot lamp.

Mechanical Signals. As has been stated the so-called mechanical signals are sometimes used in small common-battery switchboards instead of lamps. Where this is done the coil of the signal, if it is a line signal, is substituted in the line circuit in place of the relay coil. If the signals are used in connection with cord circuits for supervisory signals, their coils are put in the circuit in place of the supervisory relay coils. (These signals are referred to in Chapter III in connection with Fig. 23.) They are so arranged that the attraction of the armature lifts a target on the end of a lever, and this causes a display of color or form. The release of the armature allows this target to drop back, thus obliterating the display. Such signals, often called visual signals and electromagnet signals, should be distinguished from the drops considered in connection with magneto switchboards in which the attraction of the armature causes the display of the signal by the falling of a drop, the signal remaining displayed until restored by some other means, the restoration depending in no wise on when the armature is released.

Western Electric. The mechanical signal of the Western Electric Company, shown in Fig. 320, has a target similar to that [Page 28]shown in Fig. 254 but without a latch. It is turned to show a different color by the attraction of the armature and allowed to resume its normal position when the armature is released.

Kellogg. Fig. 321 gives a good idea of a strip of mechanical signals as manufactured by the Kellogg Company. This is known as the gridiron signal on account of the cross-bar striping of its target. The white bars on the target normally lie just behind the cross-bars on the shield in front, but a slight raising of the target—about one-eighth of an inch—exposes these white bars to view, opposite the rectangular openings in the front shield.

Monarch. In Fig. 322 is shown the visual signal manufactured by the Monarch Telephone Company.

Relays. The line relays for common-battery switchboards likewise assume a great variety of forms. The well-known type of relay employed in telegraphy would answer the purpose well but [Page 29]for the amount of room that it occupies, as it is sometimes necessary to group a large number of relays in a very small space. Nearly all present-day relays are of the single-coil type, and in nearly all cases the movement of the armature causes the movement of one or more switching springs, which are thus made to engage or disengage their associated spring or springs. One of the most widely used forms of relays has an L-shaped armature hung across the front of a forwardly projecting arm of iron, on the knife-edge corner of which it rocks as moved by the attraction of the magnet. The general form of this relay was illustrated in Fig. 95. Sometimes this relay is made up in single units and frequently a large number of such single units are mounted on a single mounting plate. This matter will be dealt with more in detail in the discussion of common-battery multiple switchboards. In other cases these relays are built en bloc, a rectangular strip of soft iron long enough to afford space for ten relays side by side being bored out with ten cylindrical holes to receive the electromagnets. The iron of the block affords a return path for the lines of force. The L-shaped armatures are hung over the front edge of this block, so that their free ends lie opposite the magnet cores within the block. This arrangement as employed by the Kellogg Company is shown in two views in Figs. 323 and 324.

A bank of line relays especially adapted for small common-battery switchboards as made by the Dean Company, is shown in Fig. 325.

Jacks. The jacks in common-battery switchboards are almost always mounted in groups of ten or twenty, the arrangement being similar to that discussed in connection with lamp strips. Ordinarily in common-battery work the jack is provided with two inner contacts so as to cut off both sides of the signaling circuit when the operator plugs in. A strip of such jacks is shown in Fig. 326.

Ringing and listening keys for simple common-battery switchboards differ in no essential respect from those employed in magneto boards.

Switchboard Assembly. The general assembly of the parts of a simple common-battery switchboard deserves some attention. The form of the switchboard need not differ essentially from that employed in magneto work, but ordinarily the cabinet is somewhat smaller on account of the smaller amount of room required by its lamps and jacks. An excellent idea of the line jacks and lamps, plugs, keys, and supervisory signals may be obtained from Fig. 327, which is a detail view taken from a Kellogg board. In the vertical panel of the board above the plug shelf are arranged the line jacks and the lamps in rows of twenty each, each lamp being immediately beneath its corresponding jack. Such jacks are ordinarily mounted on 1/2-inch centers both vertically and horizontally, so that a group of one hundred lamps and line jacks will occupy a space only slightly over 10 by 5 inches. Such economy of space is not required in the simple magneto board, because the space might easily be made larger without in any way taxing the reach of the operator. The reason for [Page 32]this comparatively close mounting is a result, not of the requirements of the simple non-multiple common-battery board itself, but of the fact that the jack strips and lamp strips, which are required in very large numbers in multiple boards, have to be mounted extremely close together, and as the same lamp strips and jack strips are often available for simple switchboards, an economy in manufacture is effected by adherence to the same general dimensions.

A rear view of a common form of switchboard cabinet, known as the upright type and manufactured by the Dean Company, is shown in Fig. 328. In this all the relays are mounted on a hinged rack, which, when opened out as indicated, exposes the wiring to view for inspection or repairs. Access to both sides of the relays is thus given to the repairman who may do all his work from the rear of the board without disturbing the operator.

Fig. 329 shows a three-position cabinet of Kellogg manufacture, this being about the limit in size of boards that could properly be called simple. Obviously, where a switchboard cabinet must be made of greater length than this, i. e., than is required to accommodate three operators, it becomes too long for the operators to reach all over it without undue effort or without moving from their seats. The so-called transfer board and the multiple board (to be considered in subsequent chapters), constitute methods of relief from such a condition in larger exchanges.

When the traffic originating in a switchboard becomes so great as to require so many operators that the board must be made so long that any one of the operators cannot reach over its entire face, the simple switchboard does not suffice. Either some form of transfer switchboard or of multiple switchboard must be used. In this chapter the transfer switchboard will be briefly discussed.

The transfer switchboard is so named because its arrangement is such that some of the connections through it are handled by means of two operators, the operator who answers the call transferring it to another operator who completes the connection desired.

Limitations of Simple Switchboard. Conceive a number of simple magneto switchboards, or a number of common-battery switchboards, arranged side by side, their number being so great as to form, by their combination, a board too long for the ordinary cords and plugs to reach between its extremities. On each of these simple switchboards, which we will say are each of the one-position type, there terminates a group of subscribers' lines so great in number, considering the traffic on them, that the efforts of one operator will just about be taxed to properly attend to their calls during the busiest hours of the day. If, now, these subscribers would be sufficiently accommodating to call for no other subscribers than those whose lines terminate on the same switchboard section or on one of the immediately adjacent switchboard sections, all would be well, but subscribers will not be so restricted. They demand universal service; that is, they demand the privilege of having their own lines connected with the line of any other person in the exchange. Obviously, in the arrangement just conceived, any operator may answer any call originating at her own board and complete the connection with the desired subscriber if that subscriber's jack terminates on her own section or on one of the adjacent ones. Beyond that she is powerless unless other means are provided.

Transfer Lines. In the transfer board these other means consist in the provision of groups of local trunk lines or transfer lines extending from each switchboard position to each other non-adjacent switchboard position. When an operator receives a call for some line on a non-adjacent position, having answered this call with her answering plug, she inserts the calling plug into the jack of one of these transfer lines that leads to the proper other section. The operator at that section is notified either verbally or by signal, and she completes the connection between the other end of the transfer line and the line of the called subscriber; the connection between the two subscribers thus being effected through the cords of the two operators in question linked together by the transfer line. Such a transfer line as just described, requiring the connection at each of its ends by one of the plugs of the operator's cord pair, is termed a jack-ended trunk or a jack-ended transfer line because each of its ends terminates in a jack.

There is another method of accomplishing the same general result by the employment of the so-called plug-ended trunk or plug-ended transfer line. In this the trunk or transfer line terminates at one end, the answering end, in a jack as before, and the connection is made with it by the answering operator by means of the calling plug of the pair with which she answered the originating call. The other end of this trunk, instead of terminating in a jack, ends in a plug and the second operator involved in the connection, after being notified, picks up this plug and inserts it in the jack of the called subscriber, thus completing the connection without employing one of her regular cord pairs.

Jack-Ended Trunk. In Fig. 330 are shown the circuits of a commonly employed jack-ended trunk for transfer boards. The talking circuit, as usual, is shown in heavy lines and terminates in the tip and sleeve of the transfer jacks at each end. The auxiliary [Page 36]contacts in these jacks and the circuits connecting them are absolutely independent of the talking circuit and are for the purpose of signaling only, the arrangement of the jacks being such that when a plug is inserted, the spring 1 will break from spring 2 and make with spring 3. Obviously, the insertion of a plug in either of the jacks will establish such connections as to light both lamps, since the engagement of spring 1 with spring 3 in either of the jacks will connect both of the lamps in multiple across the battery, this connection including always the contacts 1 and 2 of the other jack. From this it follows that the insertion of a plug in the other end of the trunk will, by breaking contact between springs 1 and 2, put out both the lamps. One plug inserted will, therefore, light both lamps; two plugs inserted or two plugs withdrawn will extinguish both lamps.

If an operator located at one end of this trunk answers a call and finds that the called-for subscriber's line terminates within reach of the operator near the other end of this trunk, she will insert a calling plug, corresponding to the answering plug used in answering a call, into the jack of this trunk and thus light the lamp at both its ends. The operator at the other end upon seeing this transfer lamp illuminated inserts one of her answering plugs into the jack, and by means of her listening key ascertains the number of the subscriber desired, and immediately inserts her calling plug into the jack of the subscriber wanted and rings him in the usual manner. The act of this second operator in inserting her answering plug into the jack extinguishes the lamp at her own end and also at the end where the call originated, thus notifying the answering operator that the call has been attended to. As long as the lamps remain lighted, the operators know that there is an unattended connection on that transfer line. Such a transfer line is called a two-way line or a single-track line, because traffic over it may be in either direction. In Fig. 331 is shown a trunk that operates in a [Page 37]similar way except that the two lamps, instead of being arranged in multiple, are arranged in series.

Plug-Ended Trunk. In Fig. 332 is shown a plug-ended trunk, this particular arrangement of circuits being employed by the Monarch Company in its transfer boards. This is essentially a one-way trunk, and traffic over it can pass only in the direction of the arrow. Traffic in the opposite direction between any two operators is handled by another trunk or group of trunks similar to this but "pointed" in the other direction. For this reason such a system is referred to as a double-track system. The operation of signals is the same in this case as in Fig. 330, except that the switching device at the left-hand end of the trunk instead of being associated with the jack is associated with the plug seat, which is a switch closely associated with the seat of a plug so as to be operated whenever the plug is withdrawn from or replaced in its seat. The operation of this arrangement is as follows: Whenever an operator at the right-hand end of this trunk receives a call for a subscriber whose line terminates within the reach of the operator at the left-hand end of the trunk, she inserts the calling plug of the pair used in answering the calling subscriber into the jack of the trunk, and thus lights both of the trunk lamps. The operator at the other end of the trunk, seeing the trunk lamp lighted, raises the plug from its seat and, having learned the wishes of the calling subscriber, inserts this plug into the jack of the called subscriber without using one of her regular pairs. When she raised the trunk plug from its seat, she permitted the long spring 1 of the plug seat switch to rise, thus extinguishing both lamps and giving the signal to the originating operator that the trunk connection has received attention. On taking down the connection, the withdrawal of the plug from the right hand of the trunk lights both lamps, and the restoring of the trunk plug to its normal seat again extinguishes both lamps.

Plug-Seat Switch. The plug-seat switch is a device that has received a good deal of attention not only for use with transfer systems, but also for use in a great variety of ways with other kinds of manual switching systems. The placing of a plug in its seat or withdrawing it therefrom offers a ready means of accomplishing some switching or signaling operation automatically. The plug-seat switch has, however, in spite of its possibilities, never come into wide use, and so far as we are aware the Monarch Telephone Manufacturing Company is the only company of prominence which incorporates it in its regular output. The Monarch plug-switch mechanism is shown in Fig. 333, and its operation is obvious. It may be stated at this point that one of the reasons why the plug-seat switch has not been more widely adopted for use, is the difficulty that has been experienced due to lint from the switchboard cords collecting on or about the contact points. In the construction given in the detailed cut, upper part, Fig. 333, is shown the means adopted by the Monarch Company for obviating this difficulty. The contact points are carried in the upper portion of an inverted cup mounted on the under side of the switchboard shelf, and are thus protected, in large measure, from the damaging influence of dust and lint.

Methods of Handling Transfers. One way of giving the number of the called subscriber to the second operator in a transfer system [Page 39]is to have that operator listen in on the circuit after it is continued to her position and receive the number either from the first operator or from the subscriber. Receiving it from the first operator has the disadvantage of compelling the first operator to wait on the circuit until the second operator responds; receiving it from the subscriber has the disadvantage of sometimes being annoying to him. This, however, is to be preferred to the loss of time on the part of the originating operator that is entailed by the first method. A better way than either of these is to provide between the various operators working in a transfer system, a so-called order-wire system. An order wire, as ordinarily arranged, is a circuit terminating at one end permanently in the head receiver of an operator, and terminating at the other end in a push button which, when depressed, will connect the telephone set of the operator at that end with the order wire. The operator at the push-button end of the order wire may, therefore, at will, communicate with the other operator in spite of anything that the other operator may do. An order-wire system suitable for transfer switchboards consists in an order wire leading from each operator's receiver to a push button at each of the other operator's positions, so that every operator has it within her power to depress a key or button and establish communication with a corresponding [Page 40]operator. When, therefore, an operator in a transfer system answers a call that must be completed through a transfer circuit, she establishes connection with that transfer circuit and then informs the operator at the other end of that circuit by order wire of the number of the trunk and the number of the subscriber with which that trunk is to be connected. Fig. 334 shows a system of order-wire buttons by means of which each operator may connect her telephone set with that of every other operator in the room, the number in this case being confined to three. Assuming that each pair of wires leading from the lower portion of this figure terminates respectively in the operator's talking apparatus of the three respective operators, then it is obvious that operator No. 1, by depressing button No. 2, will connect her telephone set with that of operator No. 2; likewise that any operator may communicate with any other operator by depressing the key bearing the corresponding number.

Limitations of Transfer System. It may be stated that the transfer system at present has a limited place in the art of telephony. The multiple switchboard has outstripped it in the race for popular approval and has demonstrated its superiority in practically all large manual exchange work. This is not because of lack of effort on the part of telephone engineers to make the transfer system a success in a broad way. A great variety of different schemes, all embodying the fundamental idea of having one operator answer the call and another operator complete it through a trunk line, have been tried. In San Francisco, the Sabin-Hampton system was in fairly successful service and served many thousands of lines for a number of years. It was, however, afterwards replaced by modern multiple switchboards.

Examples of Obsolete Systems. The Sabin-Hampton system was unique in many respects and involved three operators in each connection. It was one of the very first systems which employed automatic signaling throughout and did away with the subscribers' generators. It did not, however, dispense with the subscribers' local batteries.

Another large transfer system, used for years in an exchange serving at a time as many as 5,000, was employed at Grand Rapids, Michigan. This was later replaced by an automatic switchboard.

Field of Usefulness. The real field of utility for the transfer system today is to provide for the growth of simple switchboards that have extended beyond their originally intended limits. By the adding of additional sections to the simple switchboard and the establishment of a comparatively cheap transfer system, the simple boards may be made to do continued service without wasting the investment in them by discarding them and establishing a completely new system. However, switchboards are sometimes manufactured in which the transfer system is included as a part of the original equipment. In Fig. 335 is shown a three-position transfer switchboard, manufactured by the Monarch Telephone Company. At first glance the switchboard appears to be exactly like those described in Chapter XXI, but on close observation, the transfer jacks and signals may [Page 42]be seen in the first and third positions, just below the line jacks and signals. There is no transfer equipment in the second position of this switchboard because the operator at that position is able to reach the jacks of all the lines and, therefore, is able to complete all calls originating on her position without the use of any transfer equipment. Referring to Fig. 301, which illustrates a two-position simple switchboard, it may readily be seen that if the demands for telephone service in the locality in which this switchboard is installed should increase so as to require the addition of more switchboard positions, this switchboard could readily be converted to a transfer switchboard by placing the necessary transfer jacks and signals in the vacant space between the line jacks and clearing-out drops.

Field of Utility. The multiple switchboard, unlike the transfer board, provides means for each operator to complete, without assistance, a connection with any subscriber's line terminating in the switchboard no matter how great the number of lines may be. It is used only where the simple switchboard will not suffice; that is, where the number of lines and the consequent traffic is so great as to require so many operators and, therefore, so great a length of board as to make it impossible for any one operator to reach all over the face of the board without moving from her position.

The Multiple Feature. The fundamental feature of the multiple switchboard is the placing of a jack for every line served by the switchboard within the reach of every operator. This idea underlying the multiple switchboard may be best grasped by merely considering the mechanical arrangement and grouping of parts without regard to their details of operation. The idea is sometimes elusive, but it is really very simple. If the student at the outset will not be frightened by the very large number of parts that are sometimes involved in multiple switchboards, and by the great complexity which is apparent in the wiring and in the action of these parts; and will remember that this apparent complexity results from the great number of repetitions of the same comparatively simple group of apparatus and circuits, much will be done toward a mastery of the subject.

The multiple switchboard is divided into sections, each section being about the width and height that will permit an ordinary operator to reach conveniently all over its face. The usual width of a section brought about by this limitation is from five and one-half to six feet. Such a section affords room for three operators to sit side by side before it. Now each line, instead of having a single jack as in the simple switchboard, is provided with a number of jacks [Page 44]and one of these is placed on each of the sections, so that each one of the operators may have within her reach a jack for each line. It is from the fact that each line has a multiplicity of jacks, that the term multiple switchboard arises.

Number of Sections. Since there is a jack for each line on each section of the switchboard, it follows that on each section there are as many jacks as there are lines; that is, if the board were serving 5,000 lines there would be 5,000 jacks. Let us see now what it is that determines the number of sections in a multiple switchboard. In the final analysis, it is the amount of traffic that arises in the busiest period of the day. Assume that in a particular office serving 5,000 lines, the subscribers call at such a very low rate that even at the busiest time of the day only enough calls are made to keep, say, three operators busy. In this case there would be no need for the multiple switchboard, for a single section would suffice. The three operators seated before that section would be able to answer and complete the connections for all of the calls that arose. But subscribers do not call at this exceedingly low rate. A great many more calls would arise on 5,000 lines during the busiest hour than could be handled by three operators and, therefore, a great many more operators would be required. Space has to be provided for these operators to work in, and as each section accommodates three operators the total number of sections must be at least equal to the total number of required operators divided by three.

Let us assume, for instance, that each operator can handle 200 calls during the busy hour. Assume further that during the busy hour the average number of calls made by each subscriber is two. One hundred subscribers would, therefore, originate 200 calls within this busy hour and this would be just sufficient to keep one operator busy. Since one operator can handle only the calls of one hundred subscribers during the busy hour, it follows that as many operators must be employed as there are hundreds of subscribers whose lines are served in a switchboard, and this means that in an exchange of 5,000 subscribers, 50 operators' positions would be required, or 162/3 sections. Each of these sections would be equipped with the full 5,000 jacks, so that each operator could have a connection terminal for each line.

The Multiple. These groups of 5,000 jacks, repeated on each [Page 45]of the sections are termed multiple jacks, and the entire equipment of these multiple jacks and their wiring is referred to as the multiple. It will be shown presently that the multiple jacks are only used for enabling the operator to connect with the called subscriber. In other words these jacks are for the purpose of enabling each operator to have within her reach any line that may be called for regardless of what line originates the call. We will now consider what arrangements are provided for enabling the operator to receive the signal indicating a call and what provisions are made for her to answer the call in response to such a signal.

Line Signals. Obviously it is not necessary to have the line signals repeated on each section of the board as are the multiple jacks. If a line has one definite place on the switchboard where its signal may be received and its call may be answered, that suffices. Each line, therefore, in addition to having its multiple jacks distributed one on each section of the switchboard, has a line signal and an individual jack immediately associated with it, located on one only of the sections. This signal usually is in the form of a lamp and is termed the line signal, and this jack is termed the answering jack since it is by means of it that the operator always answers a call in response to the line signal.

Distribution of Line Signals. It is evident that it would not do to have all of these line signals and answering jacks located at one section of the board for then they would not be available to all of the operators. They are, therefore, distributed along the board in such a way that one group of them will be available to one operator, another group to another operator, and so on; the number of answering jacks and signals in any one group being so proportioned with respect to the number of calls that come in over them during the busy hour that it will afford just about enough calls to keep the operator at that position busy.

We may summarize these conditions with respect to the jack and line-signal equipment of the multiple switchboard by saying that each line has a multiple jack on each section of the board and in addition to this has on one section of the board an answering jack and a line signal. These answering jacks and line signals are distributed in groups along the face of the board so that each operator will receive her proper quota of the originating calls which she will [Page 46]answer and, by virtue of the multiple jack, be able to complete the connections with the desired subscribers without moving from her position.

Cord Circuits. Each operator is also provided with a number of pairs of cords and plugs with proper supervisory or clearing-out signals and ringing and listening keys, the arrangement in this respect being similar to that already described in connection with the simple switchboard.

Guarding against Double Connections. From what has been said it is seen that a call originating on a given line may be answered at one place only, but an outgoing connection with that line may be made at any position. This fact that a line may be connected with when called for at any one of the sections of the switchboard makes necessary the provision that two or more connections will not be made with the same line at the same time. For instance, if a call came in over a line whose signal was located on the first position of the switchboard for a connection with line No. 1,000, the operator at the first position would connect this calling line with No. 1,000 through the multiple jack on the first section of the switchboard. Assume now that some line, whose signal was located on the 39th position of the switchboard, should call also for line No. 1,000 while that line was still connected with the first calling subscriber. Obviously confusion would result if the operator at the 39th position, not knowing that line No. 1,000 was already busy, should connect this second line with it, thereby leaving both of the calling subscribers connected with line No. 1,000, and as a result all of these three subscribers connected together.

The provisions for suitable means for preventing the making of a connection with a line that is already switched at some other section of the switchboard, has offered one of the most fertile fields for invention in the whole telephone art. The ways that have been proposed for accomplishing this are legion. Fortunately common practice has settled on one general plan of action and that is to so arrange the circuits that whenever a line is switched at one section, such an electrical condition will be established on the forward contacts of all of its multiple jacks that any operator at any other section in attempting to make a connection with that line will be notified of the fact that it is already switched by an audible signal, which she [Page 47]will receive in her head receiver. On the other hand the arrangement is such that when a line is not busy, i. e., it is not switched at any of the positions of the switchboard, the operator on attempting to make a connection with such a line will receive no such guarding signal and will, therefore, proceed with the connection.

We may liken a line in a multiple switchboard to a lane having a number of gates giving access to it. One of these gates—the answering jack—is for the exclusive use of the proprietor of that lane. All of the other gates to the lane—the multiple jacks—are for affording means for the public to enter. But whenever any person enters one of these gates, a signal is automatically put up at all of the other gates forbidding any other person to enter the lane as long as the first person is still within.

Diagram Showing Multiple Board Principle. For those to whom the foregoing description of the multiple board is not altogether clear, the diagram of Fig. 336 may offer some assistance. Five subscribers' lines are shown running through four sections of a switchboard. Each of these lines is provided with a multiple jack on each section of the board. Each line is also provided with an answering jack and a line signal on one of the sections of the board. Thus the answering [Page 48]jacks and the line signals of lines 1 and 2 are shown in Section I, that of line 4 is shown in Section II, that of line 3 in Section III, and that of line 5 in Section IV. At Section I, line 1 is shown in the condition of having made a call and having had this call answered by the operator inserting one of her plugs into its answering jack. In response to the instructions given by the subscriber, the operator has inserted the other plug of this same pair in the multiple jack of line 2, thus connecting these two lines for conversation. At Section III, line 3 is shown as having made a call, and the operator as having answered by inserting one of her plugs into the answering jack. It happens that the subscriber on line 3 requests a connection with line 1, and the condition at Section III is that where the operator is about to apply the tip of the calling plug to the jack of line 1 to ascertain whether or not that line is busy. As before stated, when the contact is made between the tip of the calling plug and the forward contact of the multiple jack, the operator will receive a click in the ear (by means that will be more fully discussed in later chapters), this click indicating to her that line 1 is not available for connection because it is already switched at some other section of the switchboard.

Busy Test. The busy signal, by which an operator in attempting to make a connection is informed that the line is already busy, has assumed a great variety of forms and has brought forth many inventions. It has been proposed by some that the insertion of a plug into any one of the jacks of a line would automatically close a little door in front of each of the other jacks of the line, therefore making it impossible for any other operator to insert a plug as long as the line is in use. It has been proposed by others to ring bells or to operate buzzers whenever the attempt was made by an operator to plug into a line that was already in use. Still others have proposed to so arrange the circuits that the operator would get an electric shock whenever she attempted to plug into a busy line. The scheme that has met with universal adoption, however, is that the operator shall, when the tip of her calling plug touches the forward contact of the jack of a line that is already switched, receive a click in her telephone which will forbid her to insert the plug. The absence of this click, or silence in her telephone, informs her that she may safely make the connection.

Principle. The means by which the operator receives or fails to receive this click, according to whether the line is busy or idle, vary widely, but so far as the writers are aware they all have one fundamental feature in common. The tip of the calling plug and the test contact of all of the multiple jacks of an idle line must be absolutely at the same potential before the test, so that no current will flow through the test circuit when the test is actually made. The test thimbles of all the jacks of a busy line must be at a different potential from the tip of the test plug so that a current will flow and a click result when the test is made.